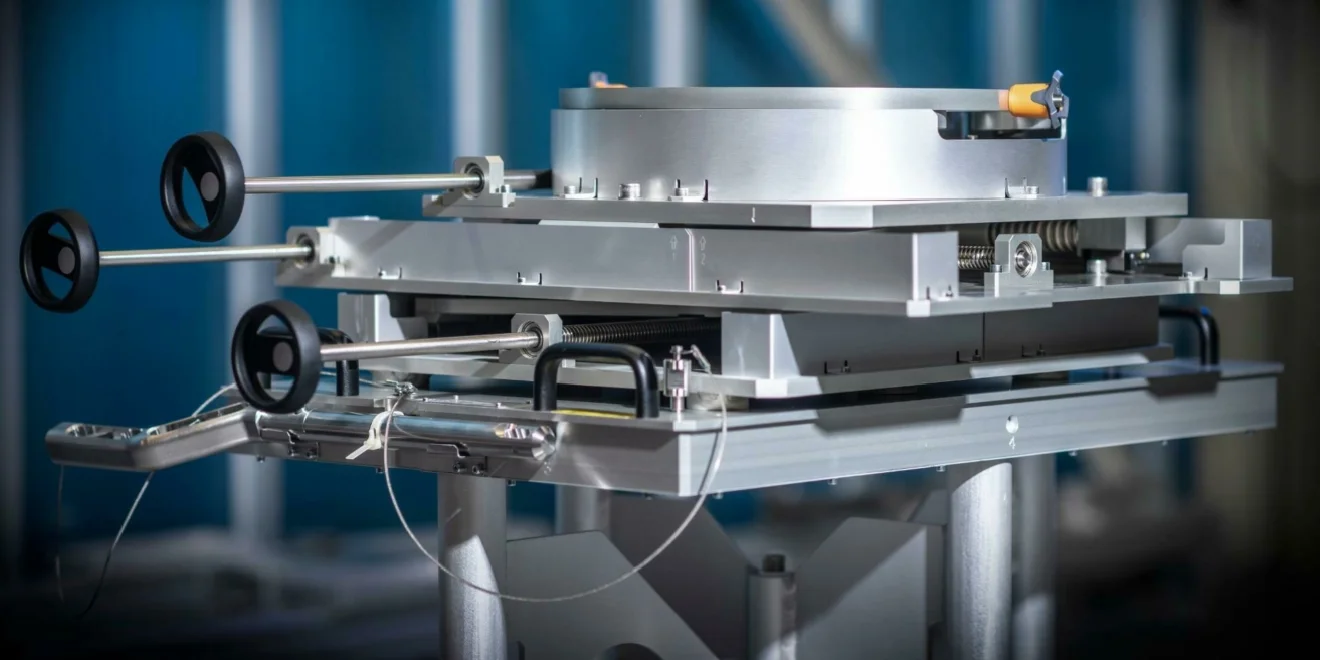

Equipment installation

Tooling

Every OEM that manufactures products tries to set up the process as efficiently as possible. Deploying the right tooling will help you achieve this. Using tooling helps you improve efficiency and productivity at the same time as you reduce your costs.

If you are looking for ways to optimize your processes further, get in touch with Tuinte. Tuinte is not just a specialist in mechanical engineering and making custom parts and components; you can also rely on our expertise for tooling.

Deploying tooling to optimise your process

- Efficiency

Improved efficiency is one of the key benefits of using tooling. Tools can simplify tasks and processes. That helps shorten production times.

- Quality

Tooling can be used to improve process accuracy and consistency. This can lead to less downtime and improved customer satisfaction.

- Lower costs

With tooling, tasks and processes can be simplified, requiring less manpower. Tools can help you reduce labour costs.

In short, deploying tooling helps you optimise the process. Tooling can also be used to make work safer and more ergonomic, contributing to better employability of staff.

Deploying tooling across the whole breadth of the process

Tooling can be used in the production process itself. Think of tools that help with assembly, for example. But tools can also help with other facets of the process, such as:

- Transport

- Lifting and hoisting

- Handling

- Production

- Testing

Why choose tooling from Tuinte?

- The combination of our many capabilities makes us strong in providing tooling

- Our engineers and craftsmen work intensively together to deliver the best tool

- Tools are made in-house – you can rely on Tuinte quality

- We have everything we need in house to create even the most complex tooling

- We have years of experience and have already delivered many different tools

- Tuinte is a reliable and stable family company, in business since 1964

- 100 professionals working together to make what we say come true