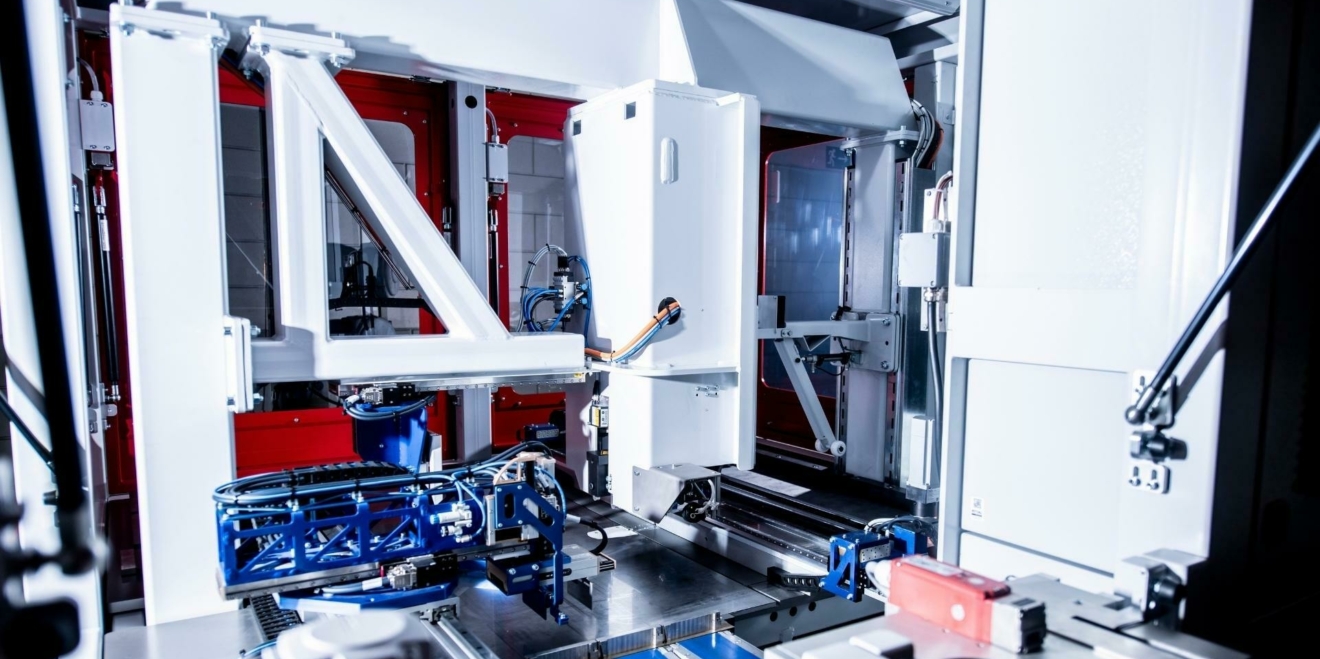

High-tech machine design

Engineering

You are looking for a unique machine for your production process, expansion of your machinery, or a machine for a new process. That new machine represents a hefty investment. That’s why you are looking for a reliable partner that delivers what it promises. A partner who communicates well and includes you in the design process. Who understands you. And, of course, a partner who provides a dedicated machine that is just as reliable.

Designing a machine for process improvement

You are shopping around for a new machine for a reason. There are many different reasons why companies turn to us to help think about how to optimise production processes. Chances are you are also looking for a partner for one of the following reasons:

- Buyers of your products have higher demands; innovation is key to meeting those demands.

- Competitors are supplying the same products at a lower price. Optimisations are needed to take a stronger position price-wise.

- Current machines no longer comply with laws and regulations in force.

- Staff costs and staff shortages. Expanding your machinery means you need fewer FTEs.

- Existing machines are in need of replacement or renewal. Downtime is increasing and maintenance costs rising.

- The workload is increasing and absenteeism is rising. It is getting harder to meet targets.

- You want to produce in a more environmentally friendly way.

Looking for a machine?

You are looking for a machine with:

- Improved takt times; makes more products in less time

- Fewer FTEs; less labour intensive

- Less downtime

- Less wastage of raw materials

- Fewer rejects and higher quality

- Lower maintenance costs

- More energy-efficiency

- Faster switchover times

- Less call on staff to operate the machine

- Seamless links to your production process

In short, you are looking for a reliable machine that will ensure you can continue future-proof production.

How we design the machine that meets your requirements

Our design team works intensively with you. We have developed our own process approach to work with you efficiently to reach the desired design. The design process runs broadly as follows:

- Drawing up specifications

Before we start designing, the specifications need to be clear. Only when we know what your new machine needs to comply with can we also make sure it will do what it needs to do. Don't have that in focus yet? No problem! We will help you.

- Aligning specifications and costs

No design is too complex for us. Need to assemble the machine? Handle small components? Or produce in bulk on the largest possible scale? Our engineers are multidisciplinary, experienced and creative in finding solutions. Lines are short, we are happy to engage with your people to come up with a good design. Together, we fine-tune the operation of the machine.

We propose a follow-up process which depends on the complexity of the project. This may include one or more of the following steps. Each step is followed by consultation with you for review and approval.

- Concept design

We create a preliminary design based on the ideas discussed. We ensure that the design fully meets the requirements set and is also practicable within the parameters agreed. Our team of machine builders is watching. After all, they’ll have to build it.

- Estimated cost

Based on the preliminary design, we will give you a indication of the cost of building the machine as designed.

- Detailed design

If the design is satisfactory and the cost estimate is agreed, we will work it out in detail. We model it completely using 3D modelling. That way we know exactly which parts are needed and how the machine should be assembled.

- From design to single level drawings

The 3D design is developed into single level drawing for production. The test plan is also being finalised.

- Design approval

The final step of the engineering process. The special machine is all set to go on paper. Do you agree? Then we can start making it happen for you.

A machine design with your ROI in mind

The new machine should contribute to the profitability of your business. You want to recoup the investment in getting your new machine designed and built as quickly as possible. And, of course, development costs need to be balanced. We help you develop a machine that fits not just your process, but your budget too. We use your metrics to calculate the Return On Investment (ROI). Is it too low? Or is your budget inadequate? Then together we will see how we can fine-tune the specifications. Feasibility and profitability are paramount.

Machine engineering for various industries

Tuinte supplies machines and machine parts for various industries.

Alongside regular machine construction, we have recently opened a new facility containing plenty of space for cleanroom activities.

Do your end-users place particularly high demands on your machines? No problem, we can meet them.

10 reasons to choose a machine design from Tuinte

- Our team consists of 12 experienced engineers (from secondary to university educated)

- We develop 2D sketches in 3D for you using SolidWorks

- No machine is too complex for us

- We design complete custom-made machines, modules and components, or a combination of them

- Our engineers and in-house machine builders work together intensively

- We have already supplied many custom-made machines

- Tuinte is a reliable family company, in business since 1964

- Machines are manufactured in-house. That contributes not just to reliability, but also to favourable delivery times

- Tuinte is a one-stop-shop for mechanical engineering. After engineering, we build the special machine in-house

- As a high-tech manufacturing partner, we add value to your production process