Cables need to last on the seabed for at least 35 years.

Machine development for Twentsche Kabelfabriek

Wind in TKF’s sails

Massive investments are being made in renewable energy sources, and the demand for green energy keeps rising. The (high-tech) industry is developing and innovating rapidly to meet that demand more efficiently. After all, we can generate energy, but we also have to be able to transport it. Twentsche Kabelfabriek (TKF), founded in 1930 in Haaksbergen, is one such tech heavyweight that is fully active in this market. With multiple sites in the Netherlands and abroad, TKF focuses on producing cables for various market segments. The energy market is currently very important for TKF. The energy transition calls for logistical solutions in which TKF’s cables transport energy across land and under water.

35 years on the seabed

In Eemshaven, TKF has a brand-new plant: state-of-the-art and CO₂-neutral. The inter-array subsea cables produced here carry power between wind turbines and the substations of wind farms. From Eemshaven, the cables are supplied worldwide for use in projects such as the new wind farms north of the Dutch and German Wadden Sea.

No one wants to write off 10 kilometers of cable

The quality requirements for subsea cables are, understandably, very high: they must be able to remain on the rugged seabed for at least 35 years. That’s why the entire process—from development to production and from winding to assembly of the cable—meets stringent standards. A wind farm outage due to a cable failure, or having to scrap 10 kilometers of cable in production, is something nobody wants.

Twentsche Kabelfabriek

Energy

Engineering machines, Mechanical engineering

A damaged cable jacket can lead to sky-high costs!

Why quality is a choice

The CO₂-neutral plant is fully operational

The enormous winding baskets, eight meters in diameter, are loaded with kilometers of subsea cable. To meet rising market demand and safeguard quality, extra capacity is required. That’s where Tuinte comes in. Tuinte had previously developed special-purpose machines for TKF to wind three-core cables: three power cores with an aluminum screen and a PE outer jacket. In these projects, Tuinte proved itself a high-tech partner to the manufacturing industry: small series, high quality and reliability, and a one-stop-shop concept—from the drawing board to on-site implementation and maintenance.

Quality must not suffer under time pressure

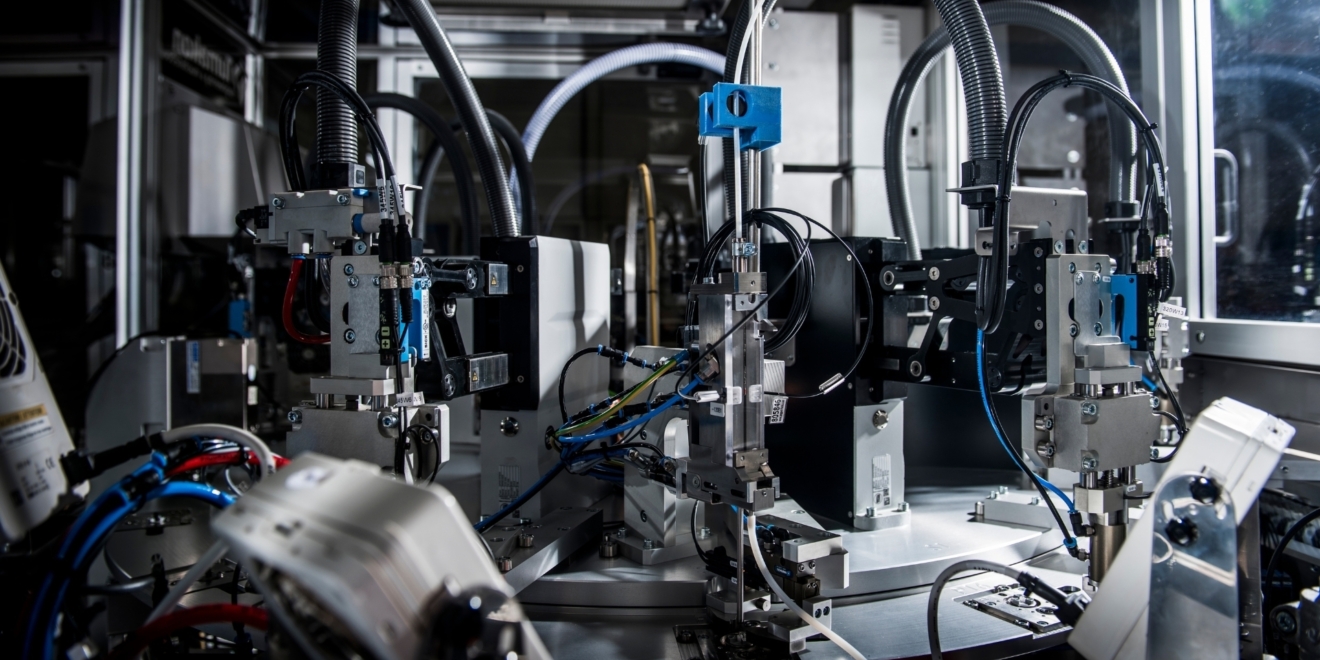

The brief is clear: develop a lay-in system that feeds the cable and deposits it into a rotating basket, along with a list of expectations and requirements the machine must meet. The solution would need to be a kind of robotic arm—a combination of mechanics and electronics with precise measuring instruments and control.

Cable lay-in cannot simply be paused; doing so can damage the cable and make it impossible to guarantee quality.

Jelle Nijhof, Lead Engineer at Tuinte, has been involved from the very start. He explains how the team began with a concept study. Despite a very tight deadline, research and testing are absolutely crucial. The entire engineering department was involved, and together with Frank and Michel we guided and directed the start-up. Strong project management across all facets is essential to safeguard quality and still meet the deadlines.

Ultimately, the pieces have to fall into place.

Approach

Martijn Tuinte speaks proudly about the test setup made specifically for this project, where a fine piece of craftsmanship is on full display. It’s rewarding when all the individual components are brought together into a single machine. A broad, satisfied grin appears on Jelle’s face as he talks about the prototype. “You work with different people on different parts; when it all finally fits together and works, that makes us happy!”

Still, this is only part of the solution. Before the cable is laid into the basket by our machine, it has to travel a path to the robot arm. The cable must not be bent at all kinds of angles, and both cable strain and feed speed have to remain constant. To safeguard quality, that requires careful tuning of the servomotors, sensors, and control software. And to prevent any loss of quality along the route to the lay-in system, we need to implement and test on site!

Opening up the roof in Eemshaven

Despite the building’s considerable dimensions, the technicians ran into a challenge. Above the baskets there wasn’t enough working height for a straight vertical feed of a conductor, core, or phase cable. A solution was found with minimal impact: a hole was made in the roof to create additional height for cable feed-through. Not a full renovation, but a smart modification to the building that keeps the cable from snaking through tight bends. The machine has been installed and is operational. The operators who will run it are receiving instruction, and the first giant baskets are being loaded with subsea cable. Both the operator panel used on the shop floor and the control cabinet and software were developed in collaboration with a Tuinte partner.

Keep it simple

Tuinte's strength

In closing, Jelle explains why Tuinte is such a good manufacturing partner for this project. The fact that we were able to deliver this system successfully and to everyone’s satisfaction in just over six months says a lot about our flexibility and capacity as an organization. For Tuinte, quality, trust, and reliability are every bit as important as they are for TKF. We’re not an enormous multinational, so short lines of communication, a well-tuned team, and having everything under one roof mean we can confidently build the right solution. That helps both us and the client sleep well at night.